Neodymium Magnets

Strong Neodymium (NdFeb) Magnets

Neodymium magnets (also known as "Neo magnets", "NdFeB magnets", “Nd Magnets”, or "NIB magnets”), are strong permanent magnets made from an alloy of neodymium, iron and boron. Part of the rare-earth magnet family, neodymium magnets have the highest magnetic properties and energy product of all permanent magnet materials. Due to their high magnetic strength, resistance to demagnetization and relative low cost, neodymium magnets are the preferred choice for many consumer, commercial, industrial and technical applications requiring optimal magnetic performance.

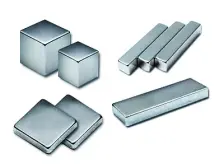

Neo Magnets In Premium Grades & Finishes

Powerful neo magnets are available in a broad range of shapes, including disc magnets, block magnets, bar magnets, ring magnets, rod magnets, countersunk magnets, channel magnets, pot magnets and hook magnets, in assorted sizes, premium grades and finishes.

Click on the images below for bulk discount pricing & sizes:

*Note: The approximate pull info listed is for reference only. These values are calculated assuming the magnet will be attached to a flat, ground 1/2" thick mild steel plate. Coatings, rust, rough surfaces, and certain environmental conditions can significantly reduce the pull force. Please be sure to test the actual pull in it's exact context. For critical applications, it is suggested that the pull be de-rated by a factor of 2 or more, depending on the severity of a potential failure.

Neodymium Magnets Features & Characteristics

- What is a neodymium magnet? Neodymium magnets are strong permanent magnets, and part of the Rare-Earth magnet family. These powerful magnets are also referred to as a "Neo”, “NdFeB", "Nd" or "NIB" magnets, as they are composed mainly of Neodymium (Nd), Iron (Fe), and Boron (B).

- Why are neodymium magnets so strong? Neo magnets are considered strong because they have a high saturation magnetization and resist demagnetization. Although they are more costly than ceramic magnets, strong neodymium magnets pack a powerful punch! Because they are so strong, smaller NdFeB magnets can achieve the same effect as larger magnets made from other materials, leading to lower overall costs for many applications as the entire device can shrink.

- How long do neodymium magnets last? Ndfeb magnets will likely lose less than approximately 1% of their flux density over a 10-year period if their physical properties remain intact, and they are not subjected to demagnetizing influences (such as high-temperatures, opposing magnetic fields, radiation etc.).

- What are the main characteristics of neodymium magnets? Nd magnets are far less subject to cracking & chipping and less costly than other rare-earth magnetic materials such as Samarium Cobalt, and are available in a wide variety of shapes, sizes and premium grades.

- What neodymium magnet grades are available? We carry a large inventory of licensed neo magnets in premium grades ranging from N30 to N52, which is the highest grade available in today's market.

- What are rare-earth magnets? Rare-earth magnets are strong permanent magnets made from alloys of rare-earth elements. They are strongest magnets available today with exceptional magnetic properties. There are two types: neodymium magnets and samarium cobalt magnets, and each has unique characteristics and attributes.

- What are permanent magnets? Permanent magnets are made from specialty alloys, and unlike temporary magnets or electromagnets, they produce persistent magnetic fields without an external source of magnetism or electric power. There are 4 main types; neodymium magnets which are the strongest permanent magnets, samarium cobalt magnets which are the most temperature stable, alnico magnets & ceramic magnets.

- What safety precautions should be taken into consideration when working with neodymium magnets? Neodymium magnets are hard, fairly brittle, and high in magnetic strength. They can snap together with great force, so please ensure that all personnel handling these magnets are aware to handle them carefully in order to avoid injuries. In particular, large neodymium magnets must be handled with extreme care as they can chip or break if dropped or if snapped together. Please plan ahead for safe handling and take special care when handling these powerful magnets.

Maximum Operating Temperatures for Neodymium Magnet Grades

Here are the maximum operating temperatures and curie temperatures for standard and specialty neodymium magnet grades:

|

NdFeB Material |

Max Operating Temp |

Curie Temp |

||

|

Grade |

ºF |

ºC |

ºF |

ºC |

|

N |

176 |

80 |

590 |

310 |

|

M |

212 |

100 |

644 |

340 |

|

H |

248 |

120 |

644 |

340 |

|

SH |

302 |

150 |

644 |

340 |

|

UH |

356 |

180 |

662 |

350 |

|

EH |

392 |

200 |

662 |

350 |

|

VH |

446 |

230 |

662 |

350 |

*Note: The maximum operating temperature for a magnet is dependent on the magnetic circuit that it is operating in. The values above are a guide assuming that the magnet is operating at a permeance coefficient of 1. The higher the permeance coefficient, the higher the temperature the magnet can operate in. The values noted indicate the temperatures at which the magnetic characteristics begin to decline more rapidly. The Curie temperature (at which the magnets become demagnetized and cannot be remagnetized) for standard neodymium magnets is 310°C or 590°F.

Industrial, Commercial, & Other Applications for Neo Magnets

Neodymium magnets are used for a wide variety of applications, including small parts and components in commercial and industrial manufacturing. Common applications range from crafts and model making projects to high-performance motors, medical instruments, audio components, POP displays, home improvement projects, hanging artwork, science projects, & manufacturing applications requiring a strong magnetic hold. Our sister company, Integrated Magnetics, is an expert at manufacturing custom magnetic assemblies for technical applications.

Custom Neodymium Magnets

We can custom fabricate neodymium magnets to fit your exact specifications using our in-house manufacturing facilities and experienced engineers. Contact us if you have questions about your design or send us a special request with your project’s specialty requirements.

Rare Earth Permanent Magnets

Magnet Shop is an industry-leading supplier of licensed rare-earth magnets and permanent magnets of all types. In addition to neodymium magnets, we offer samarium cobalt magnets, alnico magnets, ceramic magnets, and flexible magnets in premium grades, sizes and shapes. Not all of our magnets are displayed on this website, let us know if you don’t see what you are looking for.